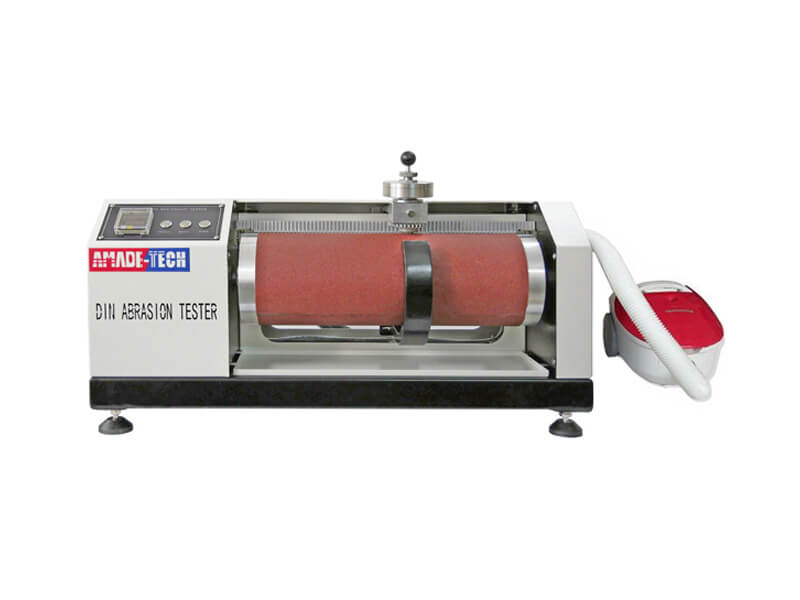

Rotary Drum Rubber Abrasion Tester

Model

AT-R7010 series

Applications

Used to determine the resistance of vulcanized rubber, elastomers and thermoplastics to abrasion.

Standards

ISO 4649, DIN 53516, ASTM D5963, JIS K6264-2, ISO 20871, SATRA TM174, etc.

Rotary Drum Rubber Abrasion Tester Description

Rotary Drum Rubber Abrasion Tester is also called DIN abrader. It is the most widely used instrument to determine the resistance of vulcanized rubber and thermoplastics to abrasion. The volume loss caused by the abrasive action of the test piece compared to a reference compound is required to be measured with this abrasion machine. Equipped with separate gadgets, it supports rotating test piece and non-rotating test piece as per needs during the test. This rubber abrasion tester is commonly used in rubber and plastics laboratories for comparative testing, checking the consistency of product quality, formulation development and so on.

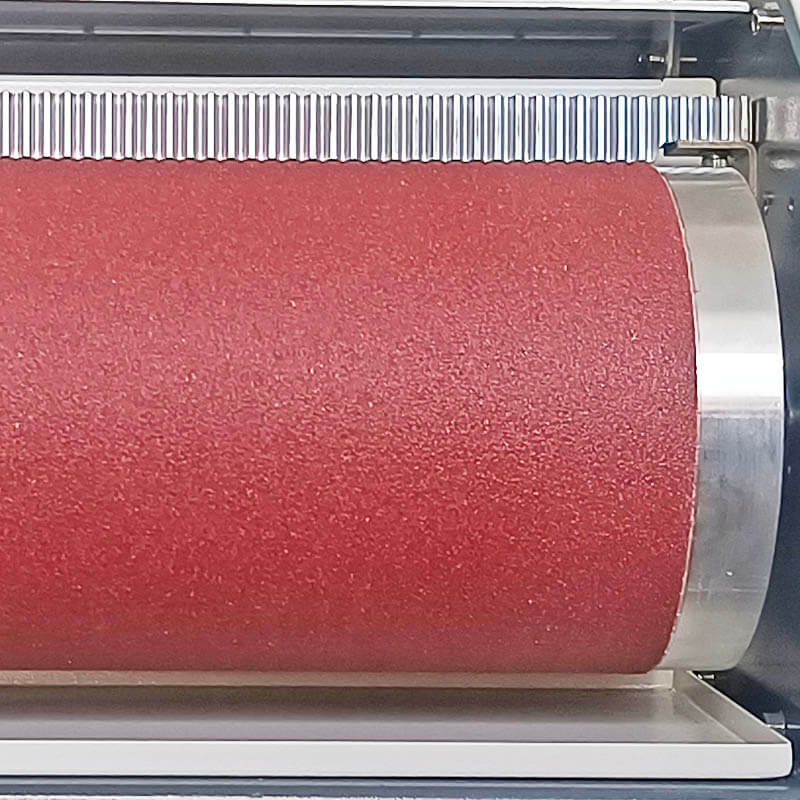

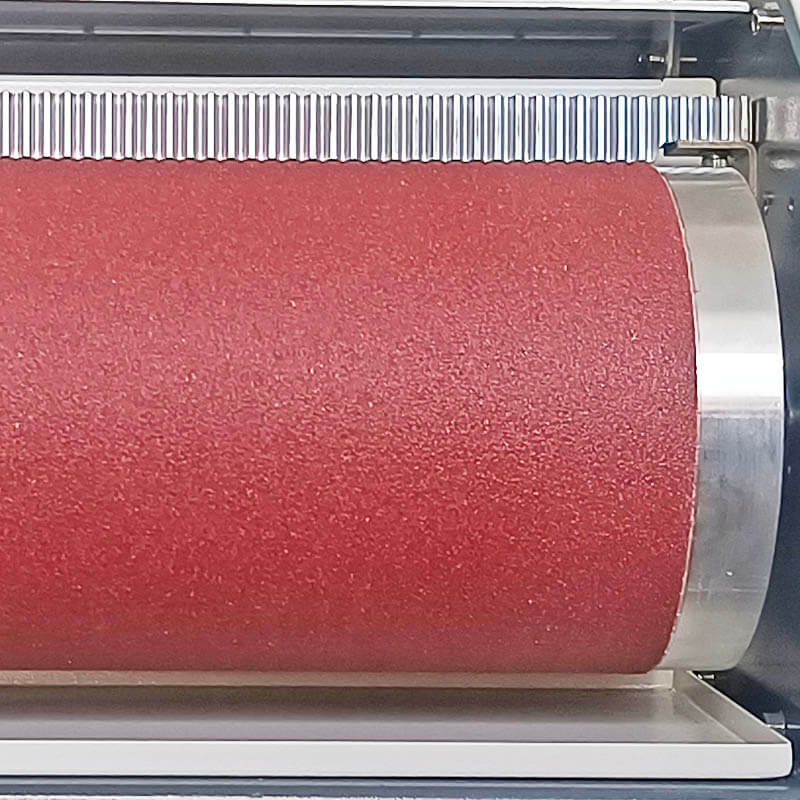

The rubber abrader consists of a rotatable drum and a laterally movable test piece holder. A piece of abrasive cloth of grain size 60 is required to be attached to the surface of the drum with double-sided adhesive tapes for the test. The diameter of the drum is 150 mm and it is able to rotate outwards at a speed of 40±1 rpm when the machine is running. The test piece holder is mounted on a swivel arm which is pivoted about a spindle. The centre axis of the holder has an inclination of 3° to the perpendicular in the direction of rotation. The holder has a cylindrical opening whose diameter can be adjusted from 15.5 mm to 16.3 mm by mean of a chuck. We configure a special gauge to ensure the length of the test piece protruding from the opening is 2 mm when mounting the test piece.

Specimen holder

We equip the swivel arm and the holder with different additional weights to allow the test piece to be pressed against the abrasive cloth with a adjustable force of 5N and 10N. As the cylinder rotates, the test piece holder can be moved on a spindle. An additional disc with gears is provided to rotate the test piece during the test run by rotation of the test piece holder. The lateral displacement of the holder is approximately 4.2 mm per revolution. The abrasion distance for a test on an ordinary test piece is 40±2 m, which is exactly the distance of 84 revolutions of the cylinder.

Entry-level rubber abrasion tester

Abrasion tester with a vacuum

Abrasion tester with a sink

In order to meet the testing needs of different users, we have different models of machines for you to choose from, including an entry-level machine, which requires the operator to manually use a brush to remove debris during the test. If you think it too troublesome to use a manual brush, you can choose a version with a vacuum dust collector, which can automatically suck away the debris on the roller and clean it up. In addition, we also have a DIN abrasion tester with a water sink. During the test, the bottom of the roller is immersed in water to complete the test. If you have more personalized needs, please contact us directly for solutions.

In addition to DIN abrasion test machine, we can also provide a series of accessories and auxiliary equipment, such as abrasive sheet from Germany, standard reference rubber, hollow drill, drill, electronic balance, etc. If you want to know more about DIN rubber abrasion test details and procedure, please click here.

Rotary Drum Rubber Abrasion Tester Video

Rotary Drum Rubber Abrasion Tester - Technical Specifications

Model | AT-R7010 series |

Specimen size | φ 16 mm, thickness: 6 ~ 15 mm |

Specimen load | 5N/10N adjustable |

Load of holder | 2.5 N |

Weights | 2.5 N + 5 N |

Drum diameter | φ 150 mm |

Rotating speed of the Drum | 40 rpm |

Abrasion stroke | 40 m / 20 m (about 84 r / 24 r) |

Lateral Displacement | 4.2 mm / r |

Inclination angle of the holder | 3° |

Counter | Digital display |

Dusting Method | Manual brushing / vacuum cleaning |

Gross Weight | About 60 kg |

Power Supply | AC 220 V / AC 110 V, 1 phase, 3 A |

Rotary Drum Rubber Abrasion Tester - Working Principle

A cylindrical rubber test piece to be tested is traversed under constant contact pressure and at a specified speed through a defined wear distance across an abrasive cloth attached to the surface of a rotating cylindrical drum, and the loss in mass is measured. The abrasive grade of the abrasive cloth is determined by the same procedure as the loss in mass of the standard rubber and is required to be within a specified range of values. The loss in mass of the rubber test piece is converted to volume loss from its calculated density, and the volume loss is compared to that of a reference rubber tested under the same conditions.

Rotary Drum Rubber Abrasion Tester - Features

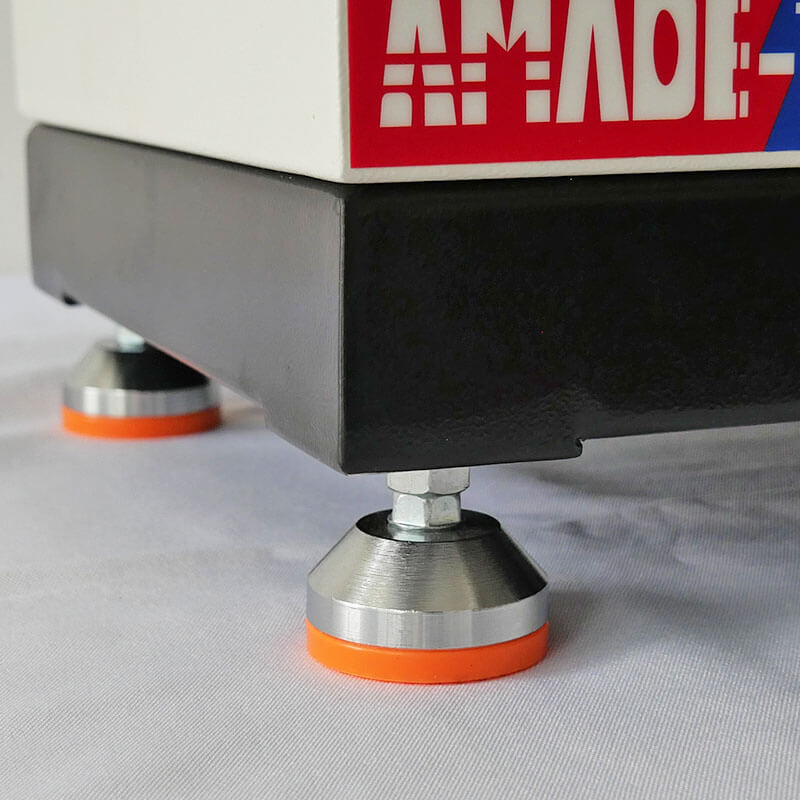

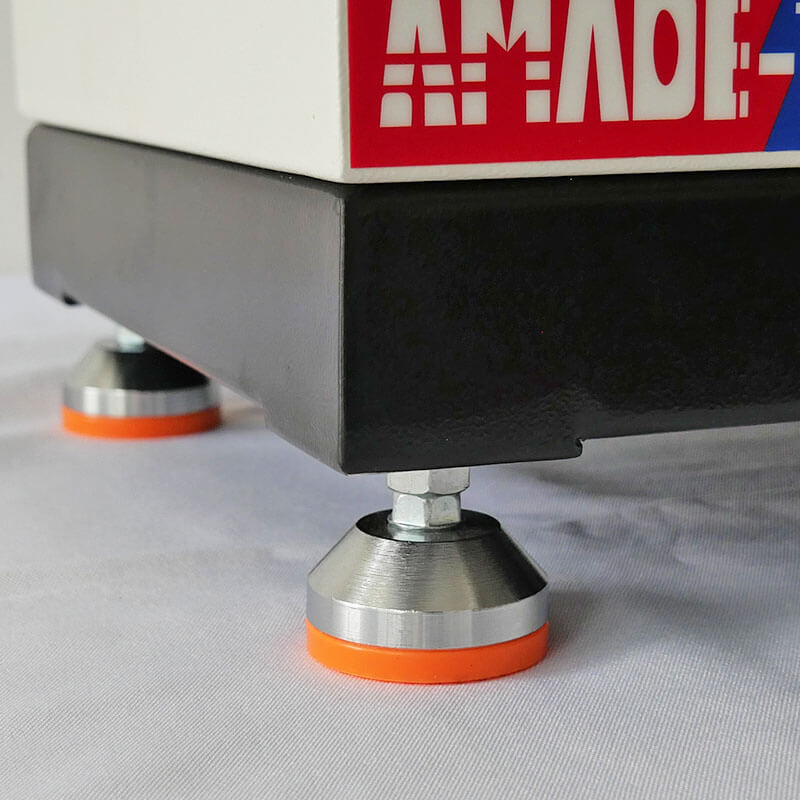

- The machine is designed in strict accordance with international standards and meets all parameters.

- Supports rotating and non-rotating specimens.

- All accessories and consumables required for testing are available from us.

- Different versions of the machine can be provided according to different needs.

- Stable and reliable quality, low failure rate.

- Simple to use and easy to maintain.

Get Free Quote of Rotary Drum Rubber Abrasion Tester that Best Meets Your Needs

Tell us about your unique testing requirements to get a personalized solution from AmadeTech